เครื่องบรรจุสุญญากาศ รุ่น VM 273 VALIDATABLE

Validatable double vacuum chamber

Large double vacuum packaging machine for heavy duty and validation. Aluminum vacuum chambers and lid with sight glass. The sight glass enables you to view your product during your packaging process.

Equipped with a strong 100 m3/h high quality Busch pump and two long seal bars in each chamber. Plug and play but if you have special validatable packing needs, no problem.

“Industrial range of efficient vacuum packaging machines suitable for multiple applications in both pharma, medical and industrial products.”

- Complies to ISO 11607-2 validation requirements for sealing

- Critical process parameters to be controlled and monitored:

- Vacuum / gas pressure

- Seal temperature

- Seal time

- Seal pressure

- Equipped with accurate Audion Temperature Controller (ATC)

- Equipped with user friendly touchscreen interface (ADC)

- Automatic stop of cycle if one of the critical parameters has exceeded alarm limit

- Critical process parameters can be calibrated

- Seal data can be logged and exported to PC via USB stick

- Access level controllable by login passwords for different user levels

- Bi-active 8mm seal bars

Benefits

- Equipped with accurate Audion Temperature Controller (ATC)

- Equipped with user friendly touchscreen interface (ADC)

- Access level controllable by login passwords for different user levels

- Bi-active seal bars

- Seal width 8 mm

- Busch vacuum pump

- Maintenance friendly and easy to clean construction

- High quality materials

- Standard with up to 50 recipe templates

- Aluminium vacuum chamber

- Aluminium lid with large sight glass

Options

- Gas flush, modified atmosphere packaging (MAP)

- Multicycle

- Unique user ID and password

- Barcode scanner

- Label printer

- Calibration

- Validation

- ESD (Electrostatic Discharge) to pack electronics, chips, motherboards and prints

- External pump

- External exhaust

Accessories

- Parameter verification

– Seal temperature verification set (ATM)

– Seal pressure verification set (ASPM)

– Vacuum pressure verification set (AVLM) - Calibration

– Audion factory calibration - IQ/OQ Check

– 1 x IQ check for 1 machine

> Operation training (max. 4 persons)

> Maintenance training (max. 4 persons)

– OQ check for 1 type of bag

> Peel test for defining seal temperature

> Peel test with defined seal temperature

> Dye penetration test

> Seal check

– Extra OQ check for each extra bag - Seal integrity test

– Seal integrity test service

> Peel test

> Dye penetration test

> Seal check

– Peel tester

– Seal check sheet

– Seal check sheet in roll

– Blue ink for dye penetration test

Markets

- Pharmaceutical

- Medical

- High-Tech

- Electronics

- Cleanrooms

SPECIFICATIONS

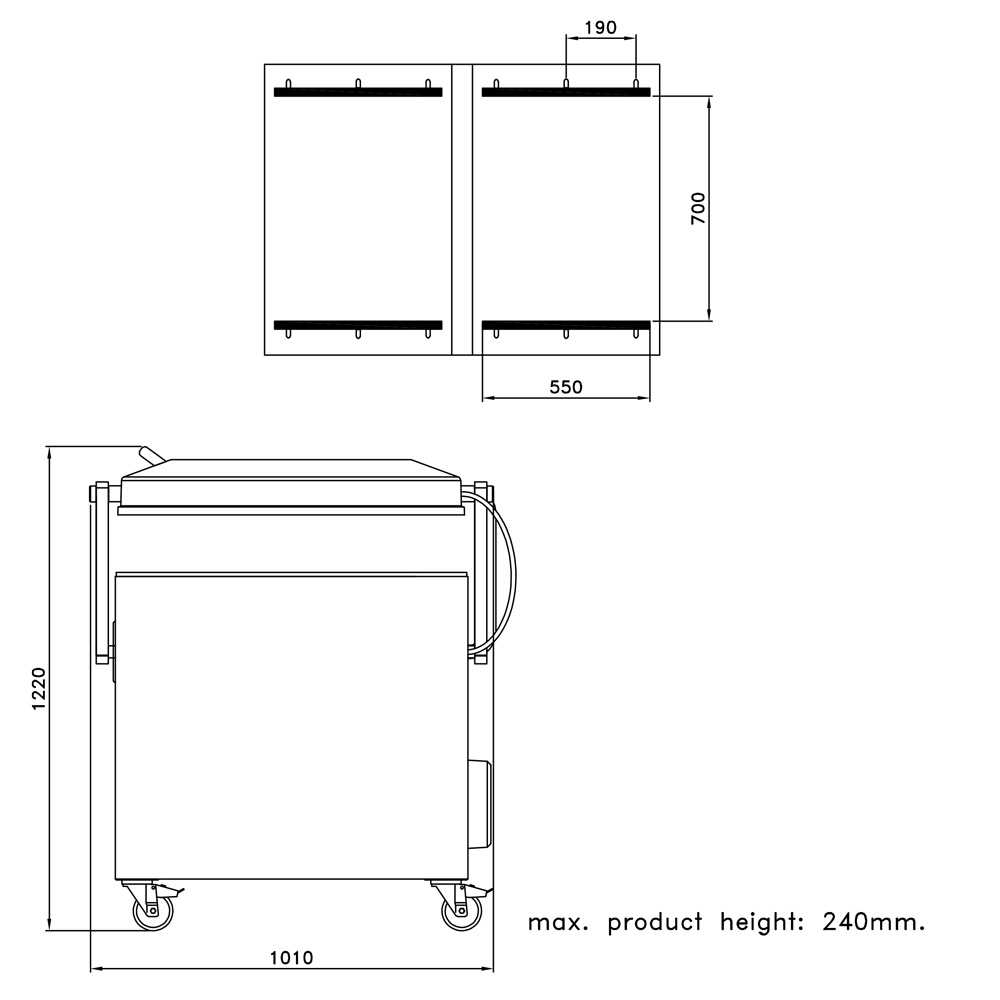

| Product | Audionvac VM 273 Validatable |

| Seal length | 550 mm |

| Seal width | 8 mm |

| Position of the sealing bar |  |

| Effective chamber size (LxWxH) | (2x) 550 x 700 x 240 mm |

| Type of machine | Validatable/calibratable/medical, Vacuum chamber, Double chamber, IQ/OQ |

| Model | Floor, Double Chamber |

| Covering | Stainless steel housing/ aluminium chamber |

| Pump capacity | 100 m3/h Busch pump |

| Pedal operated | No |

| Type of film | PA/PE, Vacuum Bags, Aluminum Laminated Bags |

| Thickness of film | 2 x 150 micron |

| Type of package | Bag |

| Branche/Application | Industrial Parts, Medical & Laboratory, Pharmaceutical Industry |

| Type of product | Solid |

| Machine cycle | 3 – 5 cycles per minute |

| Power | 3,0 – 5,0 kW |

| Pneumatic supply | 0.3 MPa |

| Voltage | 400V-3-50Hz |

| Weight | 319 kg |

| Machine dimensions (WxDxH) | 1260 x 1010 x 1070 mm |

หากสนใจเครื่อง ติดต่อเราผ่านช่องทางด้านล่างนี้ได้เลยค่ะ

โทร 0-2331-9103-6

สายด่วน 088-6422111

Line Official: @spponline