![DualX HR [Dual Energy] DualX HR [Dual Energy]](sites/10896/files/s/products/o_1h7hmbnot1151spa195patb12u77.jpg)

New Dual Energy Sensor breaks through the limits of conventional detection performance

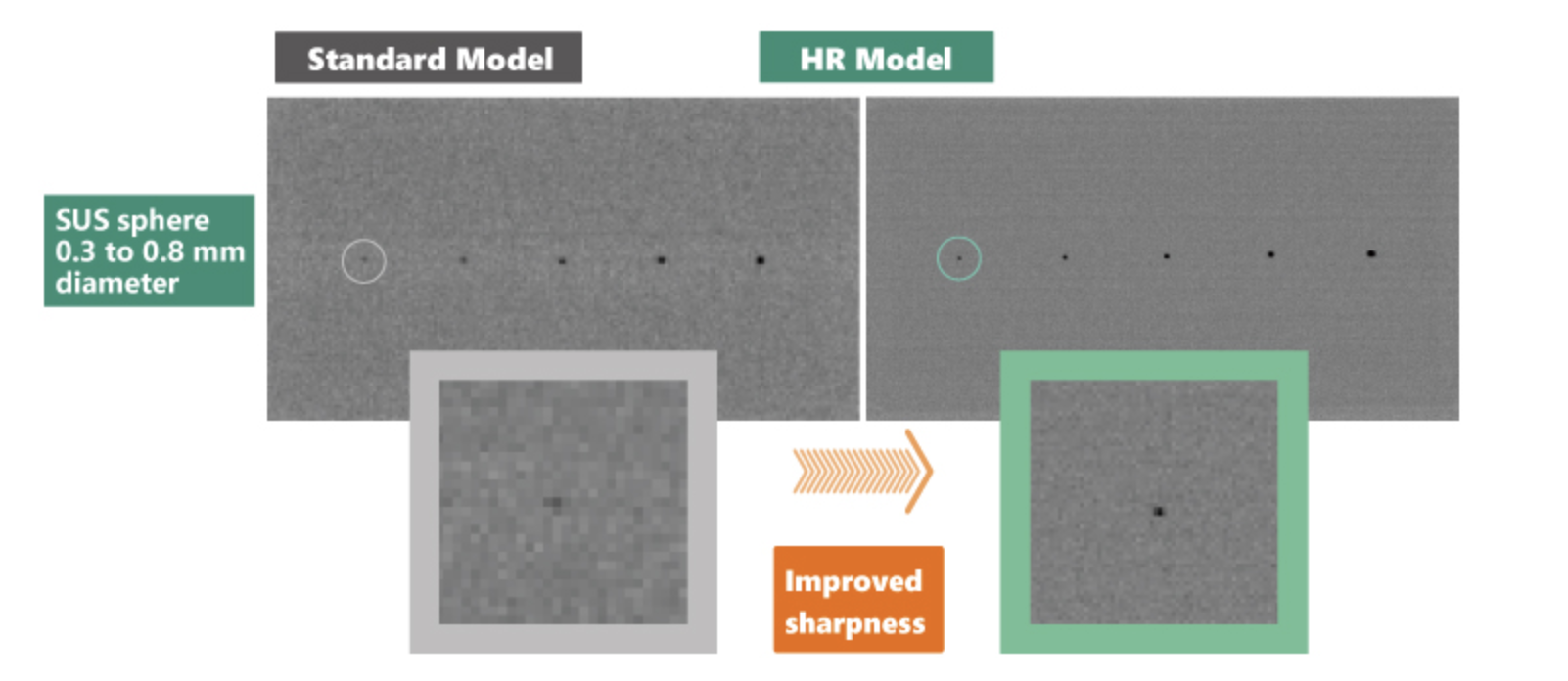

The standard dual energy model could not fully utilize its superiority of the dual energy inspection when it comes to thicker products or products with highly uneven surfaces. By introducing a new dual energy sensor, we have succeeded in making X-ray transmission images significantly sharper. It is now possible to clearly display the shadows of contaminants on these targets. In addition, the dedicated detection algorithms have improved the sensitivity to detect fine metals and small bones, which had been hard to detect.

Evolution with the new dual energy sensor

DualX HR is equipped with a high-resolution sensor to improve the sharpness of transmitted images. This makes it possible to detect foreign bodies that are even smaller in size and thinner in shape such as small bones, fine metal fragments, etc.).

Improved detection performance even for thick and unevenly shaped products

By applying the dual energy inspection method to the high-quality X-ray transmission images, it is not easily affected by the uneven shape and thickness of the product. Moreover, various type of products can be inspected thanks to the newly developed detection algorithms.

| Model | KXH7534ASGCD |

| X-ray output | Tube voltage 30 to 80 kV, Tube current 0.4 to 10.0 mA, Maximum output 300 W |

| Safety | X-ray leakage maximum 1.0 μSv/h or less, prevention of x-ray leakage by safety devices |

| Display | 15-inch color TFT LCD |

| Operation method | Touch panel (with touch buzzer) |

| Detection area1, 2 | Maximum width 370 mm, Maximum height 220 mm |

| Belt width | 420 mm |

| Preset memory | 200 |

| Belt speed3 / Maximum product weight4 | 10 to 45 m/min, maximum 5 kg |

| Power requirements5 | 200 Vac to 240 Vac, Single phase, 47 Hz to 63 Hz, 1800 VA or less |

| Mass | 350 kg |

| Environmental conditions | Temperature: 0°C to 35°C, Relative humidity: 30% to 85%, non-condensing |

| Protection class | IP66 (air conditioner: IP54) |

| Exterior | Stainless steel (SUS304) |

1 : The product size should fall below the detection area.

2 : The entrance and exit may require covers depending on the length of a product.

3 : Variable depending on Product No.

4 : Sum total of product weight on the conveyor.

5 : Allowable power fluctuation range is ±10%.